The Difference Between Steel & Aluminum: Making the Right Choice

When it comes to choosing the right material for various applications, steel and aluminum often top the list. Both materials have unique properties that make them highly sought after in different industries. In this blog entry, we will delve into the key differences between steel and aluminum, exploring their characteristics, strengths, and weaknesses. By the end, you will have a better understanding of which material suits your specific needs.

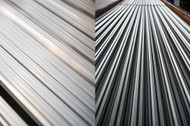

- Composition and Properties: Steel is an alloy primarily composed of iron and carbon, with small amounts of other elements. It is known for its exceptional strength and durability, making it a popular choice in structural applications. On the other hand, aluminum is a lightweight metal known for its low density and high corrosion resistance. It is commonly utilized in industries where weight reduction is crucial, such as aerospace and automotive.

- Strength and Durability: Steel is renowned for its exceptional strength and rigidity. It boasts a high tensile strength, making it ideal for applications that require heavy loads or structural stability. In contrast, aluminum is not as strong as steel, but it compensates with its lightness. While aluminum is less dense, it still maintains sufficient strength for many applications, especially when combined with other alloys to form composite materials.

- Weight and Density: One of the most significant advantages of aluminum over steel is its low density. Aluminum is approximately one-third the weight of steel, making it an excellent choice for applications where weight reduction is critical, such as in the automotive and aerospace industries. By utilizing aluminum, manufacturers can create lighter, more fuel-efficient vehicles without compromising structural integrity.

- Corrosion Resistance: Another important aspect to consider is the materials' corrosion resistance. Aluminum naturally forms a protective oxide layer when exposed to oxygen, providing excellent resistance to corrosion. This property makes aluminum a popular choice for outdoor applications, such as window frames, gutters, and other architectural elements. Steel, however, is prone to rust when exposed to moisture and requires protective coatings to prevent corrosion.

- Heat Conductivity: Aluminum possesses exceptional heat conductivity, making it a preferred material in industries that require efficient heat dissipation. It is commonly used in heat sinks for electronic devices, radiators, and other cooling systems. Steel, while not as efficient in heat transfer, has its own advantages, such as its ability to withstand high temperatures without deforming or melting. This makes it suitable for applications that require heat resistance and structural integrity, such as industrial machinery.

- Cost Considerations: Cost is often a crucial factor in material selection. Steel is generally more cost-effective than aluminum due to its abundant availability and lower production costs. Aluminum, on the other hand, is more expensive due to the energy-intensive processes required to extract and refine the metal. However, the overall cost depends on factors such as application requirements, quantity, and market conditions.

Choosing between steel and aluminum ultimately depends on the specific application and the properties desired. Steel excels in strength, durability, and heat resistance, making it suitable for structural applications and high-temperature environments. On the other hand, aluminum's lightweight nature, corrosion resistance, and excellent heat conductivity make it an attractive option for industries focused on weight reduction and efficient heat dissipation. By carefully considering the properties and requirements of your project, you can make an informed decision and select the material that best meets your needs.