Unlocking Aluminum Heat Sink Extrusion Abilities: Key Benefits

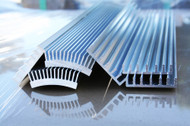

Many power-hungry electronic and mechanical equipment produce high temperatures, which if not addressed properly can lead to equipment failure. This is where aluminum heat sinks can help. The aluminum heat sinks are extrusion profiles that help regulate the temperature of power hungry mechanical and electronic equipment by transferring the heat to the environment or liquid coolant. This enables the system to function properly without getting overheated.

Copper is another most popular material used for making the heat sinks, however, its applications are limited. Aluminum heat sinks are extremely popular over copper heat sinks due to different advantages it offers. This post explores the reasons behind this popularity.

The Power of Aluminum Heat Sink Extrusions: Exploring Key Benefits and Applications

Copper has been immensely used in electronic circuits for their conductivity. However, their application as heat sinks is still limited due to various reasons. Aluminum heat sink extrusions are integral part of several small and large electronic equipment due to price advantages and several other benefits they offer. This section explores some key reasons for their popularity.

- Resists Corrosion and Oxidation: Extruded aluminum heat sinks can resist rust or corrosion, which assures their performance and long shelf life in applications where they are used. The surface of these heat sinks feature a thick solid oxide layer, which can easily withstand high temperatures for a long time.

- Excellent Thermal Conductivity: Aluminum is known for its thermal conductivity by which it can efficiently take away heat from the heat source. This property enables aluminum heat sinks to dissipate heat produced by electronic components during working such as GPUs, CPUs, power amplifiers, and LED modules.

- Improved Energy Efficiency: Thanks to its excellent thermal performance, the aluminum heat sinks do not experience thermal throttling. This results in efficient operation, as well as reduced energy consumption of devices.

- Minimized System Noise: Unlike heat sinks made of other metals, the aluminum heat sink profiles do not use passive cooling solutions, which helps reduce the system noise, as well as leads to quitter operation in factory environments.

- Lightweight: As generally known, aluminum is a lightweight material when compared to copper, steel, or any other metal used for making heat sinks. This property makes it a suitable choice for applications where weight can be a concern, such as portable electronic devices, automotive and aerospace applications. Integrating aluminum heat sink profiles help keep the overall weight low.

- Cost-effective: Aluminum heat sinks can be availed in different designs, such as stamped heat sinks, pin-fin heat sinks, extruded heat sinks, folded fin heat sinks, and so on. Among these, the extrusions are most popular because they are easy to make and available in low cost. Adding to this, aluminum heat sinks can dissipate more heat and can maintain their durability and reliability in the long run. All these factors make it a cost effective choice.

- Improved Sense of Security: Aluminum heat sink extrusions can resist impact, pressure, temperatures, and possess low risk of damage even during handling, installation, and removal. These factors create a sense of security among users.

- Customization: Aluminum heat sink profiles made by extrusion allow high level of flexibility, which means, they can be easily customized to meet your application requirements. Customized heat sinks can improve the thermal performance, as well as fit into the available space.

- Recyclability: Mounting electronic waste is a big concern in the US and worldwide. According to Time Magazine , every day Americans discard 350,000 cell phones as well as 120,000 laptops. Another report by EPA states that 3.14 million tons of electronic waste was generated in the US alone in 2013. With increasing concerns over the electronic waste, the demand for recyclable components for electronic equipment is on rise. So, the recyclability of aluminum comes as a big news for electronic equipment manufacturers looking for effective ways to reduce their carbon footprint. Aluminum heat sink profiles can be recycled at the end of their lifetime, which would help reduce electronic waste, as well as conserve resources.

- Excellent Thermal Mass: Aluminum heat sinks possess excellent thermal mass, which means they can be absorb heat and retain them for a certain time before dissipating. This property helps stabilize the temperatures, as well as minimize temperature fluctuations in the system.

Are you looking for high quality aluminum heat sinks for your sensitive electronic devices? If yes, you can partner with Orange Aluminum. We take pride in our American-made extruded heat sink stock, which is easy to install, secure, and complies with the Restriction of Hazardous Substances Directive (RoHS). These aluminum heat sinks are provided in custom lengths, finishes, and profiles to meet your application requirements. Do you want to buy them in bulk? You can take advantage of our volume pricing. Our experts will do everything to assure the best prices possible. Contact us today to explore our possibilities of working together.